|

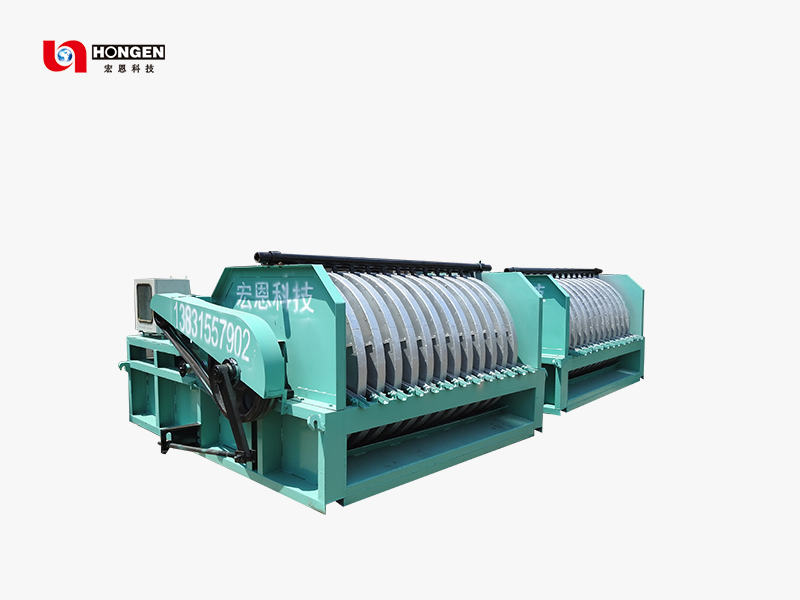

New-style self discharging tailings recycling machine’s application and characteristics:

Its magnetic discs use strong and weak magnet masses cooperating with magnetic induction to discharge the tailings. Generally, it is installed in the process of mill plant tailings launders, when tailings flowing through recycler, iron ore is absorbed to the noncorrosive outside plate because the running-off magnetic iron in tailings contacts with the magnetic pole in the recycler completely, then, the iron ore flows into the launders automatically with the plate turning to the highest and the discs’ magnet disappearing gradually, high work efficiency, reduce the magnetic iron powder grade in tailings to 3%-2% below, as a result, improve the beneficiation recycling rate. This kind of machine is a little expensive than energy-efficient equipments.

Self discharging tailings recycling machines’ advantages:

1.Surface field strength(outside disk field strength) is about 3600-4000hz

2.Recycling rate is 3-5 times higher than scraper recyclers’ and induction aluminum recyclers’.

3.It is self discharging, doesn’t need to be scraped or washed by water, and is in a state of slight breakage, namely, almost in a state of no need to be maintained.

4.Strong permeable-magnet property, no zero-magnet field area between disc and disc, which has a good effect on absorbing materials.

5.Magnetic iron can be reduced to 0.4-1 tails.